The Building Research Systems, Inc. (BRS) Research and Development design group decided to take a “blank page” redesign approach to advance the TS-324 Fixed Clip designs while improving its function, capabilities and performance to meet the numerous new challenges facing our licensees throughout the United States and Canada. BRS periodically conducts rigorous internal product reviews of our industry leading standing seam roofing systems and their components. These investigative assessments include examining current market trends, updated code criterion, component design capabilities, machinery tooling and ways to provide better element performance to maintain your leadership position within the metal roofing system industry. The latest BRS evaluation revealed the current TS-324 fixed clip tooling dies would necessitate a substantial investment for a total mechanical rebuild required to continue to supply high quality products. After a lengthy comprehensive review of the TS -324 current fixed clip designs, it was discovered the parts needed modification and upgrades to meet the new stricter energy codes, additional standoffs (that match the MPS series additions) and to improve overall roofing system performance.

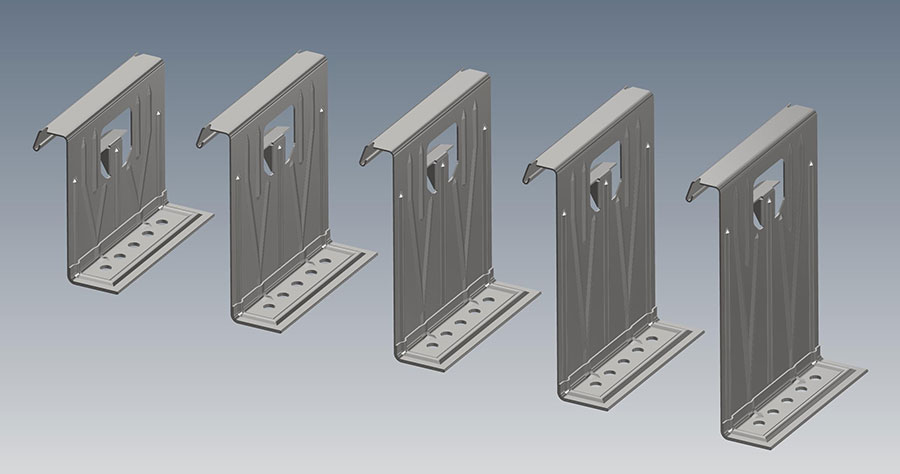

BRS utilizing our proprietary Superior Seam Technology™ (SST) methodology of design has succeeded in establishing significant advantages with the complete redesigned TS-324 fixed clips over the current parts. The “blank page” total clip redesign approach resulted in a part that contains 60% + more steel for a stouter built clip with a dual folded extended base for improved fastener pull over performance. The improved design includes four (4) attachment holes to match the long base MPS clips for an improved field connection area and an additional fifth hole delivering better installation options on cold formed joists. The clips were enhanced with added stiffener ribs that provide better rotational and lateral stiffness, higher standoff heights, much improved base performance, better resistance to purlin roll including greater diaphragm characteristics.

The clip redesign provides three (3) additional clip height options never before available in a TS-324 fixed clip. The added clip standoff heights will allow thicker single layer fiberglass insulation blanket systems to meet the ever changing energy codes for “Green Design” or stricter higher energy savings mandates being instituted by federal entities, state, county and local municipalities across the United States including Canada. Previously, Licensee sales and design teams had only three (3) fixed clip choices to select. However, the redesigned TS-324 fixed clip has increased the part offering from three (3) standard parts standoff heights of 0”, ½” and 1-1/2’” to a total of five (5) options. The redesigned parts incorporate an additional 2”, 2-1/2” and 3” extended standoff clip possibilities for flexibility of design to meet thicker thermal blanket or insulation system requirements. However, due to lack of usage, the 0” standoff TS -324 fixed clips will no longer be produced or available after the current part inventory is exhausted.

The redesigned clips are UL listed and have been independently ASTM E-1592 tested with results that are comparable to the current MPS series clip performance. The additional clip heights will allow retrofitting over existing thru fastened metal roofs much easier and less expensive on roof slope projects that qualify. These advances will keep BRS license holders the leaders in the industry for providing the pinnacle in metal standing seam roofing system technology design performance to their customers for years to come.

The current fixed clip tooling has been retired after its final production cycle was completed. There will be no additional current design TS-324 fixed clips available for purchase once the current inventories are depleted at Logan Stamping and Excel Stamping. The current TS-324 fixed clip FC461, FC462, and FC463 parts will be phased out over the next few months as stock available for purchase are consumed. The existing clip tooling was dismantled to make room for the new redesigned part tooling. Please note that if a project receives a mixture of both style fixed clips, the owner, architect, installer, or inspectors may have concerns due to the vastly redesigned parts. However, the existing fixed clip designs remain fully functional/usable parts that should be utilized on projects presently under construction or in the future if any of these clips are in licensees’ inventories. The redesigned parts can be inter-mixed with the existing clip designs since both are the same exact height for ½” and 1-1/2” parts. Therefore, the existing clip design should be utilized until all stock inventory is exhausted whether located in licensees’ internal reserves or through BRS strategic partners: Excel Stamping-Cypress, TX, or Logan Stampings-Logansport, IN inventories. The redesigned TS-324 fixed clips FC602 (1/2”) , FC603 (1-1/2”), FC 607(2” standoff), FC608(2-1/2” standoff) and FC609 (3” standoff) overall improvements will give BRS license holders an advantage over all their competitors due to the versatility , performance, and improved design options that no other standing seam roofing system can match.

The “Blank Page” redesigned TS -324 fixed clips are currently available through BRS strategic partner Logan Stampings - Logansport, IN. Please contact them for your competitive advantage for the finest fixed clip innovation offered within the metal standing seam roofing systems industry. The ASTM E-1592 test data files can be found in the licensee’s section of the BRS website.

PRODUCT RETIREMENT NOTICE:

The old-style slotted rake /eave plates RP-038 and RP-138 will be retired as of December 31, 2020. If you have not made the conversion over to the latest industry benchmark for rake/gable eave uplift performance. Please contact BRS for details or assistance to accommodate the step up to the patented High Capacity Rake and/or Starter Plates that minimizes stricter edge/corner zone code concerns for project design.

PRIVACY | ACCESSIBILITY STATEMENT | NEWS | BLOG | CAREERS