The Superior Seam Technology™ (SST) Trapezoidal mechanically field seamed TS-324 roof system continues to be the tested industry leader for highest wind uplift resistance, lowest air/water infiltration, weatherability and longevity. So, what can any licensee do with one minor change to improve upon such success with very little additional expense? The minor change that adds improved roof system performance and additional installation assistance to erectors is utilizing a heavier CC324-18 (18-gauge) corrugation closure in lieu of the more mainstream lighter CC324 (24-gauge) part installed on many standing seam roof projects.

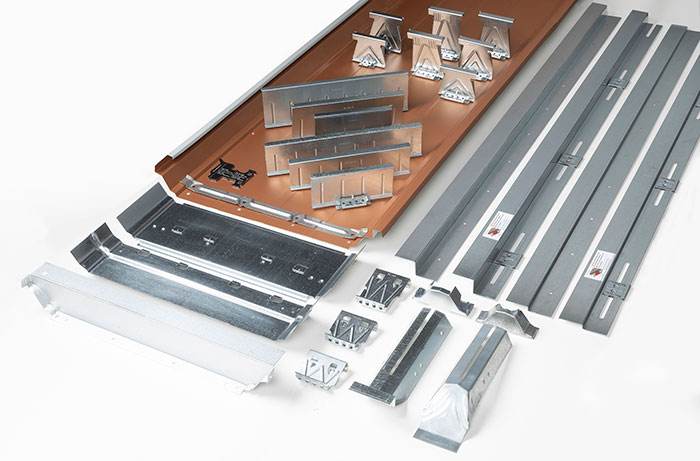

Some of the noted advantages of using the heavier 18-gauge parts are they provide a better opportunity to maintain panel modularity and allows the use of side shoulder fasteners into the corrugation closures. The use of side shoulder fasteners promotes greater uniform compressibility of the applied tape sealants due to the heavier gauge acting more like a nut (corrugation closure), tape sealant, washer (metal panel) and bolt (fastener) detail that assists to the transfer of the corrugation load to the eave plate. The 18-gauge corrugation closure used in conjunction with the newly redesigned 16-gauge high capacity eave plates with pre-punched ¼” round holes at 6” on center makes the installation process easier while assuring proper fastener locations to safeguard maximum uplift performance and weatherability when properly installed with the correct sealants. BRS urges all license holders to consider improving their TS-324 roof system performance with the utilization of the CC324-18 heavier gauge corrugation closures for their sidewall eave system installation details.

Product retirement notice:

BRS wishes to keep all license holders informed of improvements and changes and reminds all licensees that the current RP-038 and RP-138 Rake Eave plate tooling will be retired December 31, 2020. We recommend those licensees that have not transitioned over to the patented High Capacity Rake plate with the accompanying pre-punched low eave plate to do so at their earliest opportunity. As previously announced, BRS has developed a specialty variation of the patented part presently available in either an “L” or modified “Z” shape continuous starter support for use in lieu of current starter clips for the panel starter condition.

Please contact BRS for assistance to incorporate the High Capacity Rake / Specialty Support Plate into your standard panel starter details.